The biggest trick to fixing something broken is diagnosis, or identifying what to fix in the first place. When it comes to vexing mechanical problems there is probably no greater source of mystery than car noises. Pinpointing the source of the sound in question is the key to victory, and there is no better tool for this task than the simple mechanic’s stethoscope. For just a few bucks you can make like Marcus Welby, Motor Doctor and figure out exactly which bearing, lifter, injector, idle air controller pintle, or air conditioning magnet clutch has gone bad in a just few seconds.

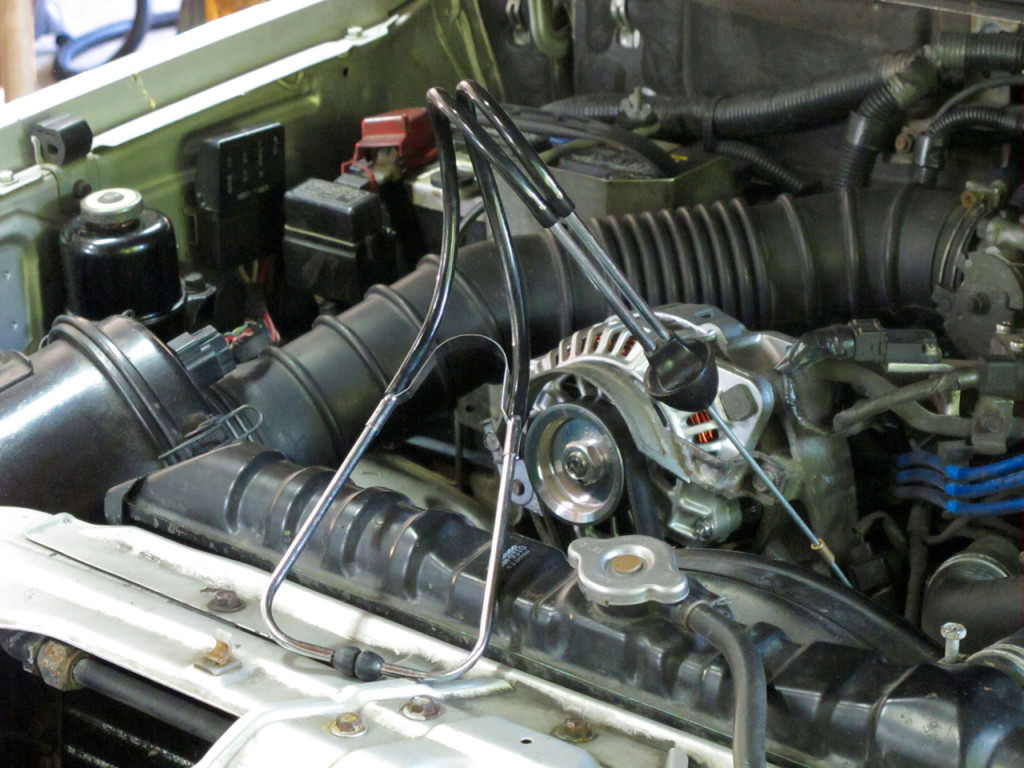

One even more basic method of focusing these unwanted sounds into your ear is to use a cut off broomstick, but the stethoscope isolates and amplifies sound precisely and clearly. Just put the ear buds in, carefully place the tip of the stethoscope where you think the problem is, and listen in. That lifter tick will be louder than bombs when you get to that spot on the valve cover. That bad alternator bearing will sound like a rock crusher. And in the case of the Vermontero, it was immediately apparent that the water pump bearing was kaput when the stethoscope tip was placed on the timing cover.

Belt driven accessories such as alternators and air conditioning compressor clutches are famous for making a racket when bearings go south. Idler pulleys are another prime noise suspect. The reason why it is a sensible plan to replace a water pump if it is driven by the timing belt is demonstrated in this mercifully short potato quality video, which shows exactly where the water pump is on a Mitsubishi 6G72 3.0-liter V6 engine, as well as the grating sound it makes when the bearing is done. Do be careful when touching the end of the stethoscope near anything that is in motion. The tool is connected to your ears after all.

Mechanic’s Stethoscopes are available almost everywhere for around a sawbuck. Here is what a bad water pump bearing sounds like through the ear buds.